Glaxo opens $120M upgrade at its Upper Merion anti-cancer factory

GSK's upgrade in Upper Merion will further accelerate its portfolio of cancer drugs. “In 2018 we had 8 oncology products in our pipeline. Today it’s 17.”

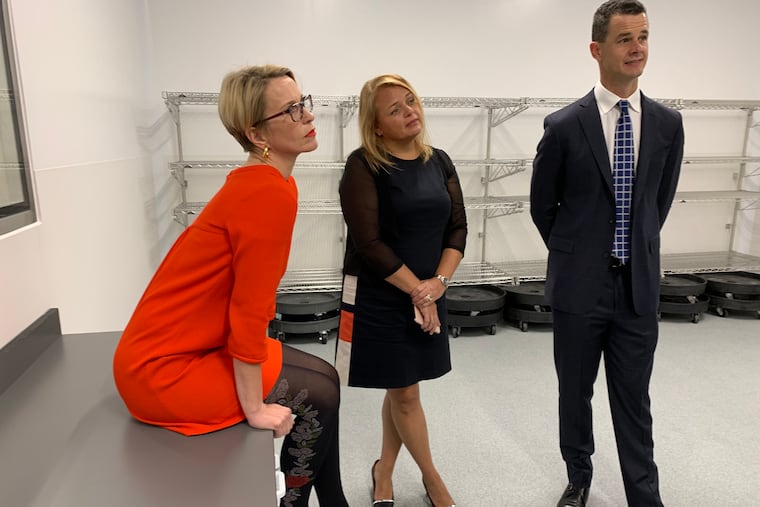

GlaxoSmithKline PLC, the big U.K.-based drugmaker with roots in Philadelphia, marked a $120 million upgrade of its biopharmaceuticals manufacturing complex with a visit from CEO Emma Walmsley, who says automation and improvements will help get its “next generation” of cancer treatments to market “years” faster.

Walmsley said Glaxo had considered moving the work elsewhere as it adds oncology and immunology products, but after a “global search,” decided to improve the existing plant because of its veteran staff and the Philadelphia-area’s status as “a great center of [medical] technology. It’s also a great market for innovation. We are betting on the people here.”

The move to update the Schuylkill River Road facilities just north of West Conshohocken is part of a $400 million Glaxo modernization effort that also includes improvements at Glaxo’s biopharma factory in Rockville, Md., and its Hamilton, Mont., vaccine works, said Kirk Brown, Glaxo’s vice president for biopharmaceuticals and sterile manufacturing.

The upgrades won’t change Glaxo’s Philadelphia-area employee totals, company officials said. It will preserve Glaxo jobs at the facility, which employs about 350, and a next-door research and development site, which employs about 550. Glaxo also employs about 3,000 at its general R&D center in Collegeville and 1,000 at its business offices in Philadelphia.

Brown, a Philadelphia native (St. Joe’s Prep, Princeton, Wharton), said improvements include automation equipment, improved data connections between labs and production sites, and controlled environments, where medicines that may sell for a million dollars a batch, or more, can be reliably produced.

The improvements standardize Glaxo’s manufacturing techniques so they can be tested and changed quickly at labs and factories around the world, Brown said. “We are using much smaller, more-flexible piping,” disposable and recyclable materials, and other improvements that reduce water use.

Glaxo typically starts biopharma production with a single milliliter vial of new product, grows it into batches of more than 1,000 liters within 40 days, then reduces the product to a suitcase- or handbag-sized batch that can be frozen for shipping and speedy use.

Three to five workers can manage three production batches in each of several growing and processing rooms. Increased automation tends to “eliminate the chance of human error,” but Glaxo has retrained longtime workers in the software and system maintenance needed to run new machines, Brown added.

Glaxo will be able to discount almost $3 million from its taxable income under Pennsylvania’s Qualified Manufacturing Innovation and Reinvestment Deduction Program. Worldwide, the company made profits of $4 billion last year, on sales of $31 billion.

Among the first of a new wave of treatments Glaxo expects to make in Upper Merion (alongside current medicines) is ICOS — the “inducible T-cell co-stimulatory” receptor agonist — which has been in clinical trials for head and neck squamous cell carcinoma (skin cancers).

CEO Walmsley has been beefing up Glaxo’s formerly depleted cancer-fighting capabilities as well as its vaccines unit, while making plans to spin off its consumer products group, in partnership with Pfizer, into a separate drugstore supply company.

In 2009, just 2% of Glaxo biopharmaceutical sales were large-molecule, complex proteins; today it’s more than half, Brown said. “In 2018, we had eight oncology products in our pipeline. Today it’s 17.”

The investment renews the company’s commitment to keep making treatments at the River Road complex, where Glaxo sold a neighboring office facility in 2017; and to Glaxo’s R&D operations in Upper Providence Township, a 20-minute drive to the west, where Glaxo employs more than 3,000 at its R&D center and labs.

Developer Brian O’Neill and his partners have been marketing the former Glaxo office space to life-science companies.

Upper Merion is one of nine Glaxo manufacturing sites in the U.S. Philadelphia was home to Glaxo’s U.S. predecessor, Smith, Kline & French. The company has another major U.S. hub in North Carolina.

Besides the suburban labs, warehouses, and factory, the company has offices in Philadelphia. In 2013, Glaxo consolidated the last occupants of its former 800,000-square-foot Center City high-rise complex into a new 200,000-square-foot building at the Navy Yard, which now employs about 1,000 sales, marketing, and other personnel.

The Upper Merion factory, built in 1996, was designed to make and ship products made from cell cultures, such as Nucala, an asthma treatment.

“The newly outfitted manufacturing space is made to be more flexible than traditional pharmaceutical manufacturing equipment,” Glaxo said in a statement. “Upper Merion uses emerging technologies in bioreactors, such as single-use and disposable components, which eliminates the need for complex retrofitting and sterilizing that is typical in most manufacturing plants.” The complex will also include a new analytical lab, “streamlined” quality and commercial testing, and closer links between research and production.

Glaxo is also looking to broaden the uses of its new treatments.